BDSM Furniture Plans for Practical, Custom Lifestyle Creations

Hey there! So, you're looking to build some custom BDSM furniture? Awesome! This isn't your average IKEA project, that's for sure. We're talking about creating pieces designed for comfort, safety, and enhancing your unique play style. Whether you're a seasoned pro or just starting to explore, building your own furniture can be incredibly rewarding. It allows for total customization, ensuring everything fits perfectly with your preferences and body type. Plus, there's a real sense of accomplishment in creating something so personal.

Understanding Your Needs: Before You Even Grab a Saw

Before diving into plans, let's talk about what you actually need. This isn't a one-size-fits-all situation. Think about:

Your Play Style and Preferences:

What kind of BDSM are you into? Different styles require different furniture. Are you focused on restraint? Suspension? Impact play? Knowing this helps determine the essential features your furniture needs. For example, a suspension rig needs incredibly strong anchors and sturdy construction, while a comfortable bondage chair might prioritize padding and adjustability.

Space and Budget:

How much space do you have dedicated to your play area? A sprawling dungeon is very different from a smaller, more intimate setup. This dictates the size and complexity of your projects. Your budget also plays a huge role. Certain materials (like stainless steel) are more expensive than others (like wood). Planning ahead helps you choose the right materials and designs within your means.

Safety First!:

Safety should always be your top priority. This means using high-quality materials and hardware capable of handling stress and weight. Consider things like:

- Strong, secure anchoring points for suspension systems.

- Padding to prevent bruising or injury during restraint.

- Easy-to-use release mechanisms for all restraints.

- Durable materials that can withstand the rigors of play.

Choosing Your Materials: Strength and Aesthetics

The materials you choose significantly impact the durability, safety, and aesthetic of your furniture. Here are some popular options:

Wood:

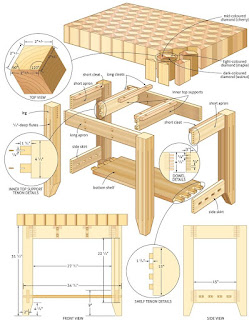

Wood is a classic choice for BDSM furniture, offering a natural look and feel. Hardwoods like oak or maple are strong and durable, but softer woods like pine are easier to work with for beginners. Remember to properly seal and finish the wood to protect it from moisture and wear.

Metal:

Metal, particularly stainless steel, is extremely strong and durable. It's ideal for suspension systems and other applications requiring significant load-bearing capacity. However, metal can be more challenging to work with, requiring specialized tools and skills.

Leather and Upholstery:

Leather and other upholstery materials are essential for adding comfort and cushioning. Look for durable, easy-to-clean materials that can withstand regular use. Consider the breathability of the material, especially if you'll be using the furniture for extended periods.

Sample Project Ideas: From Simple to Advanced

Let's brainstorm some project ideas to get your creative juices flowing:

A Simple Bondage Chair:

A basic bondage chair is a great starting project for beginners. You can build it from wood, incorporating padded restraints and comfortable cushioning. This project allows you to practice basic woodworking techniques while creating a functional and safe piece.

An Advanced Suspension Rig:

This is a much more complex project, requiring significant woodworking or metalworking skills. It involves building a sturdy frame with secure anchor points for ropes and slings. Remember that safety is paramount here. Make sure you understand the physics of suspension and have the appropriate safety measures in place.

A Customizable Restraint Table:

A restraint table can be customized to incorporate various restraints and features, making it incredibly versatile. It allows for a wide range of play styles, offering both comfort and secure restraint.

Finding Plans and Resources

Finding detailed plans for BDSM furniture can be tricky. While many online resources offer DIY furniture plans, specialized BDSM furniture plans are less common. Consider these options:

- Search for specialized forums and communities: Many online communities dedicated to BDSM have members who share their DIY projects and plans.

- Commission custom designs: If you're not comfortable building it yourself, consider commissioning a custom-made piece from a skilled craftsperson.

- Adapt existing furniture plans: You can adapt existing furniture plans (like chair or table plans) to incorporate BDSM-specific features.

Commonly Asked Questions

Here are some questions I frequently get about building BDSM furniture:

Q: Is it safe to build my own BDSM furniture?

A: Yes, it can be, but only if you prioritize safety throughout the process. Use high-quality materials, follow proper construction techniques, and thoroughly test your creation before use.

Q: What tools do I need?

A: The tools you need will depend on your chosen project and materials. Basic woodworking tools (saw, drill, sander) are a good start. For metalwork, you'll need more specialized equipment.

Q: Where can I find the right hardware?

A: Hardware stores, online retailers, and specialized BDSM suppliers offer a range of hardware suitable for BDSM furniture. Look for high-quality, heavy-duty items.

Q: How do I ensure my furniture is comfortable?

A: Consider using comfortable padding and upholstery. Ergonomics also play a crucial role. Design the furniture to support the body's natural curves and avoid pressure points.

Q: What if I make a mistake?

A: Don't worry! Everyone makes mistakes. Take your time, plan carefully, and don't be afraid to ask for help. You can always adjust your plans or start over if necessary.

Remember, building your own BDSM furniture is a journey of creativity and self-expression. Have fun, stay safe, and enjoy the process!